System integration for areal optical subsystems

- Contact:

PD Dr. Ulrich Gengenbach,

Dr. Bernd Köhler - Project Group: System integration - system-, process- and equipment development

- Funding:

HGF POF III, EU

- Partner: IMT/KIT, HHI, Holoxica

- Startdate:

2014

Description:

X-ray imaging is a well-established process in medicine, biology, and material science and is used to obtain information about the internal structure of definite solids. The principle is based on the irradiation of the object with X-ray light and the recording of the absorption image. This absorption contrast method requires relatively high irradiation doses at a comparatively low resolution depending on the object being inspected. The phase contrast method via Talbot interferometry uses the phase information of the X-ray light after the object irradiation as an additional source of information. The images obtained: absorption image, phase image, and dark-field image provide much more information about the internal structure of the examined objects. One key feature of this method is the introduction of additional grids in the beam path before and after the object. The Institute of Microstructure Technology (IMT) of the KIT manufactures the required grids. Typical external dimensions of such grids are usually around 50mm x 50mm. Constructing an X-ray system for the phase contrast method requires grid sizes that are in the range of the size of the object being examined. Thus, applications in human medicine will require grid sizes of up to 400mm x 400mm in the future (e.g., for chest examination).

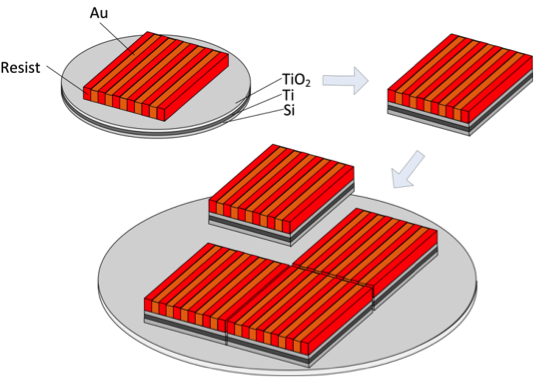

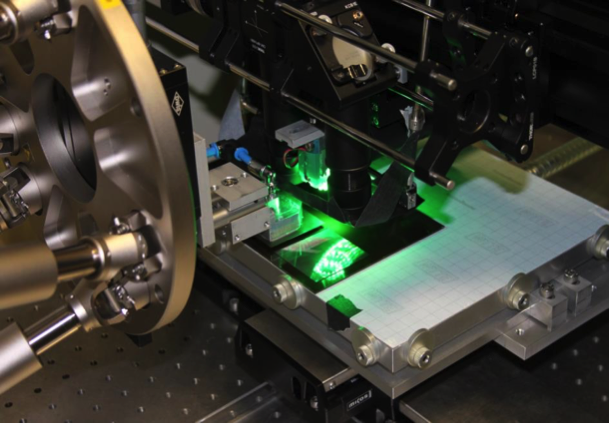

A technique for large-scale production of suitable grids for the phase contrast method is currently being worked on in close cooperation with the X-ray optics group at the IMT. The individual grids are mounted on a carrier substrate as individual tiles. The constraints of this assembly depend on the X-ray optical requirements. The assembly is done on a specifically designed prototypical mounting platform (see image) that is currently in operation at the IMT. The areal expansion will be done in several stages: 100mm x 100mm (4 tiles), 200mm x 200mm (16 tiles or another scaling format), 400mm x 400mm (no. of tiles depending on the scaling format) (see Figure 1). The mounting technology is based on the precise handling of thin, large-area substrates with sensitive structures and adhesive bonding technology tailored to the requirements (Figure 2).

The technology is also used in other projects (see EU Project: ACTPHAST Holoxica). The techniques developed at the IAI for the precise assembly of sensitive, micro-structured components form the basis for other activities, e.g., in the optics assembly field as well as the handling in micro-system technology and related areas. The activities entail the design and construction of assembly equipment as well as the implementation of the processes.

see EU-Projekt: ACTPHAST/Holoxica - Reliable fabrication route of diffractive optical elements for holographic volumetric displays

Figure 1:Tiled alignment of a large X-ray grid, source: IMT

Figure 2:Assembly platform for high-precision mounting of flat components, prototype, source: IMT